This article is part of my KPI deep-dive series for field service and after-sales organizations, where I break down commonly used metrics beyond surface-level definitions. After exploring First-Time Fix Rate (FTFR) in the first article, it’s natural to move to another widely tracked but frequently misinterpreted metric: Mean Time to Repair (MTTR). MTTR is easy to calculate and easy to report, which is precisely why it’s often used incorrectly.

On its own, MTTR can tell a misleading story. Used thoughtfully, however, it becomes a valuable indicator of service capability, process maturity, and operational constraints.

What It Really Measures

Mean Time to Repair (MTTR) measures the average time required to restore an asset to operational condition after a failure occurs.

Definition:

MTTR = Total Repair Time ÷ Number of Repair Events

On paper, MTTR appears to be a simple efficiency metric. In reality, it measures the end-to-end readiness of a service organization, from failure recognition and job preparation through diagnosis, repair, and validation.

In manufacturing and automotive service environments, MTTR is rarely driven by technician hands-on time alone. It is influenced by diagnostic accuracy, availability of parts and tools, clarity of work instructions, scheduling decisions, access constraints at customer sites, and escalation effectiveness. As Gartner has repeatedly highlighted in service and asset management research, repair duration is a system outcome, not an individual performance measure.

Put simply: MTTR reflects how well your organization removes friction from the repair lifecycle.

Why it Matters

MTTR matters because it directly affects asset availability, cost-to-serve, and customer trust – the three outcomes that manufacturing service leaders are accountable for.

Longer repair times increase equipment downtime, disrupt production schedules, and expose organizations to SLA penalties or contractual risk, especially in uptime-based or outcome-based service models. IDC research on asset-intensive industries consistently shows that unplanned downtime is one of the most expensive operational risks manufacturers face, with service responsiveness playing a decisive role in mitigating that risk.

From a financial perspective, rising MTTR drives secondary costs: additional labor hours, repeat dispatches, expedited parts shipments, and increased coordination effort across planning, logistics, and engineering. From a customer perspective, MTTR shapes perception, not just of service speed, but of competence and reliability.

This is why MTTR frequently appears on executive dashboards and board-level operational reviews.

Why MTTR Increases, and How to Improve It

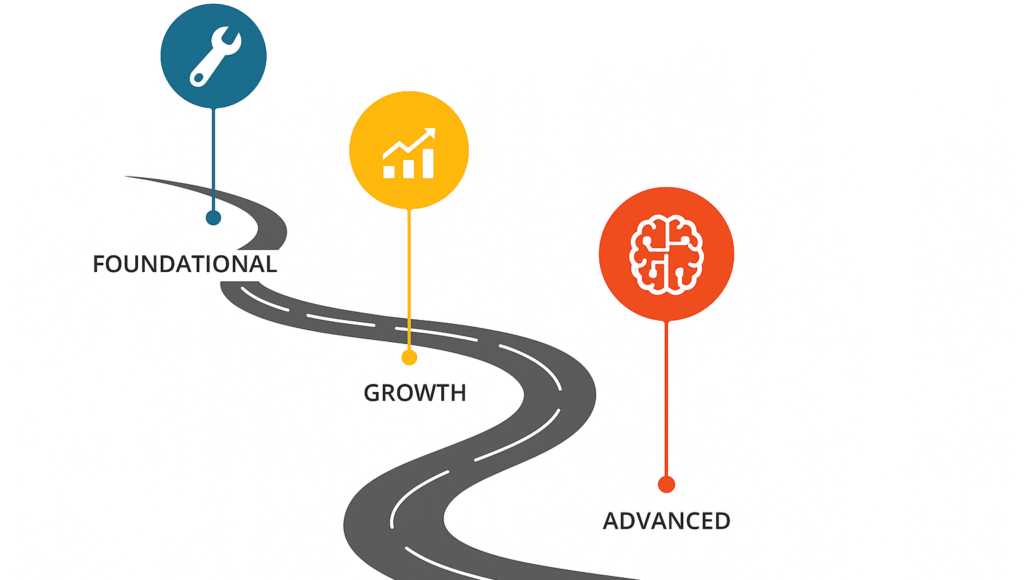

When MTTR increases, it is rarely due to technicians “working slower.” In most manufacturing and automotive service organizations, rising MTTR is a signal that organizational constraints are accumulating faster than capability is improving. MTTR improves when organizations remove friction before the technician begins the repair and not by pushing technicians to work faster once they arrive. Here are the key action-oriented points to focus on to improve MTTR:

People

- Strengthen diagnostic capability, not just repair skills, through targeted training on failure analysis and troubleshooting.

- Reduce dependency on tribal knowledge by capturing expert insights and common failure patterns in structured knowledge assets.

- Enable faster escalation and collaboration between field technicians, product engineering, and technical specialists.

- Shift performance mindset from “repair fast” to “diagnose right,” especially for complex or safety-critical assets.

Process

- Improve job scoping at dispatch by ensuring failure descriptions, asset history, and prior service actions are complete and accurate.

- Standardize repair workflows with clear start and end points to reduce variability in how MTTR is measured and managed.

- Proactively stage parts for known failure types instead of reacting after technicians arrive on site.

- Build closed-loop feedback into repeat or long-duration repairs to identify systemic delays and recurring bottlenecks.

- Segment MTTR by asset class and failure type to focus improvement efforts where downtime impact is highest.

Technology

- Provide technicians with real-time access to asset history, service manuals, and known failure resolutions in the field.

- Use remote diagnostics and condition monitoring to shorten diagnosis time before dispatch.

- Integrate field service, asset management, and parts systems to eliminate manual coordination and data gaps.

- Enable guided repair and decision-support tools to reduce dependency on experience alone.

- Improve visibility into parts availability and lead times to prevent idle waiting during repairs.

What Good MTTR Looks Like

There is no universal “good” MTTR number across manufacturing and automotive service. Acceptable repair times vary based on asset complexity, criticality, service model, and contractual commitments.

High-performing organizations focus on consistency, segmentation, and trend improvement, rather than chasing a single benchmark. They measure MTTR by asset class and failure type, monitor variability, and prioritize reductions where downtime risk and customer impact are highest.

Importantly, mature service leaders recognize that an aggressively low MTTR is not always healthy. When speed is optimized at the expense of diagnosis quality or validation, repeat failures increase, shifting cost and frustration downstream. A stable, predictable MTTR paired with strong resolution quality is a far more reliable indicator of service maturity.

Related Metrics

MTTR is most meaningful when reviewed alongside complementary after-sales KPIs, including:

- First Time Fix Rate (FTFR) – quality of resolution on the first visit

- Repeat Visit Rate – indicator of rework and diagnostic accuracy

- Mean Time Between Failures (MTBF) – asset reliability and design robustness

- Parts Fill Rate – readiness of supply chain to support service

- Schedule Adherence – effectiveness of planning and dispatch

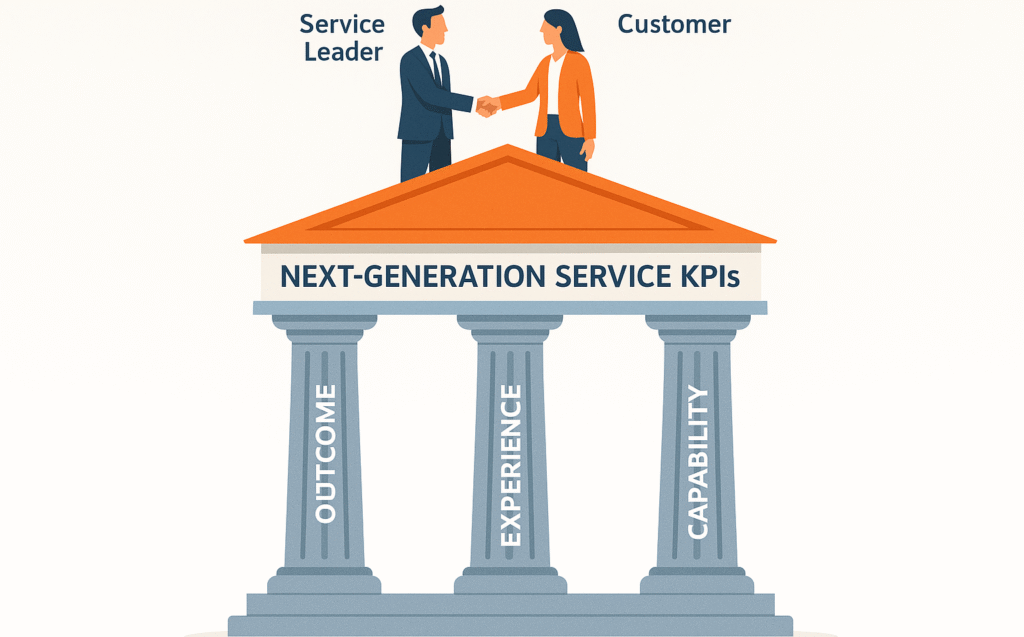

Together, these metrics provide a holistic view of service performance, balancing speed, quality, cost, and customer impact.

MTTR is not just a measure of how fast repairs happen, it is a reflection of how well your service organization prepares for failure. When leaders treat MTTR as a system metric rather than a technician scorecard, it becomes a powerful lever for improving uptime, cost efficiency, and customer confidence.