This case study illustrates how a global material handling equipment manufacturer improved service performance by addressing a fundamental execution gap: technicians were spending too much time searching for information instead of fixing equipment.

Dealer technicians struggled to access the right service guidance at the right moment, leading to low first-time fix rates, longer repair cycles, and avoidable truck rolls. Rather than introducing another portal or over-scaling AI, the organization focused on technician cognition at the point of service.

By implementing a cognitive, search-driven technician self-service experience, the manufacturer reduced diagnostic friction and enabled faster, more confident repairs. The result was a ~15% improvement in equipment uptime, reduced MTTR, higher FTFR, and millions in dealer cost savings.

The case also highlights a mature approach to AI adoption. A GenAI proof of concept was explored but not scaled due to governance risks and limited incremental value over an already high-performing solution.

Key Takeaway

Service transformation delivers the greatest impact when it reduces cognitive load for technicians, not when it adds more systems or complexity.

Digital transformation in manufacturing often promises sweeping gains through new platforms, AI, and automation. In reality, the biggest improvements frequently come from solving far more fundamental problems, especially in after-sales service.

This case study draws from hands-on experience working with a global material handling equipment manufacturer struggling with inconsistent service outcomes across its dealer network. Despite having extensive service content and experienced technicians, the organization faced low first-time fix rates, prolonged repair times, and avoidable truck rolls.

The turning point was not a new system or AI breakthrough, but a shift in how the organization understood technician cognition at the moment of service.

Service performance is often constrained by how information is accessed, not by how much information exists.

Context

The manufacturer sold and serviced a broad portfolio of material handling equipment through an extensive dealer ecosystem. Dealer technicians were responsible for on-site service across diverse asset configurations, operating conditions, and customer environments.

Over time, the manufacturer had built a rich repository of service manuals, troubleshooting guides, service bulletins, and training materials. On paper, the knowledge base was strong. In practice, technicians struggled to use it effectively in the field.

The service organization began to see worrying trends:

- Variability in service quality across dealers

- Increasing mean time to repair

- Lower equipment uptime than contractual and customer expectations

- Rising dealer service costs due to repeat visits

The problem wasn’t effort or intent- it was friction at the point of execution.

The Business Challenge

At the core of the challenge was a disconnect between how service knowledge was structured and how technicians actually worked.

Technicians needed fast, situational answers while standing next to a machine, not lengthy documents or static manuals. Instead, they were forced to:

- Search across multiple repositories

- Interpret generic procedures for highly specific asset variants

- Rely on senior technicians for guidance

- Make judgment calls under time pressure

This resulted in predictable downstream effects:

- Customers experienced avoidable downtime

- First-time fixes suffered because diagnoses were incomplete

- Repairs took longer than necessary

- Dealers absorbed the cost of repeat truck rolls

This was not a “lack of knowledge” problem- it was a “right answer, right moment” problem.

The Insight That Reframed the Solution

Through technician journey mapping and dealer interviews, one insight consistently surfaced:

Technicians were not looking for documents- they were looking for answers.

Their mental model resembled consumer search behavior:

- “What should I check next?”

- “Has this issue occurred before?”

- “What usually resolves this symptom on this asset?”

Once this was acknowledged, the direction became clear. The solution could not be another portal or reorganized document library. It had to reduce cognitive load during service execution.

The Approach – Shift to Cognitive Technician Self-Service

The team worked closely with the manufacturer to design a cognitive technician self-service experience, built around how technicians think, not how content is stored.

The approach combined three principles:

First, technician journeys were mapped end-to-end, highlighting moments where time, confidence, and accuracy broke down. Second, service content was unified across sources but surfaced contextually rather than hierarchically. Third, the experience was designed to feel intuitive, closer to a Google-like search than an enterprise system.

Instead of asking technicians to navigate content, the system worked to bring the most relevant resolution paths forward automatically.

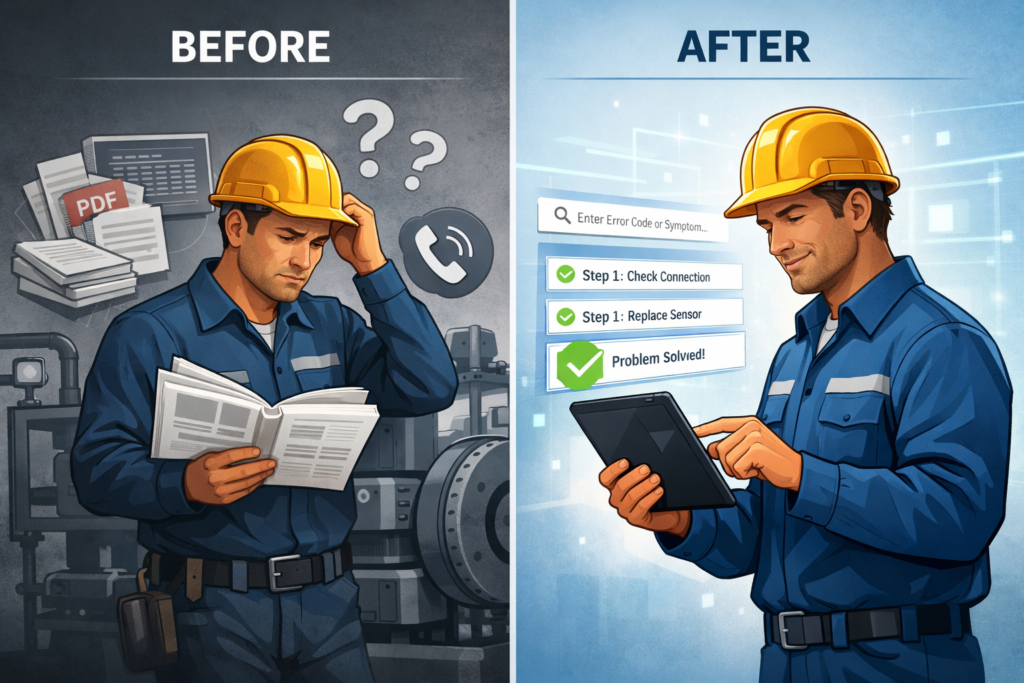

Before vs After: The Technician Experience

The impact of this shift is best understood by comparing a technician’s day before and after the solution.

Before, a service call involved fragmented workflows. Technicians moved between PDFs, legacy systems, and phone calls to senior colleagues. Diagnoses were slow, and confidence depended heavily on individual experience rather than system support.

After, technicians could enter symptoms or error codes into a single interface and receive prioritized, context-aware guidance. The system pointed them toward likely root causes, relevant fixes, and known resolutions, dramatically reducing guesswork.

The difference wasn’t just speed, it was clarity.

When service systems think less like repositories and more like copilots, outcomes change.

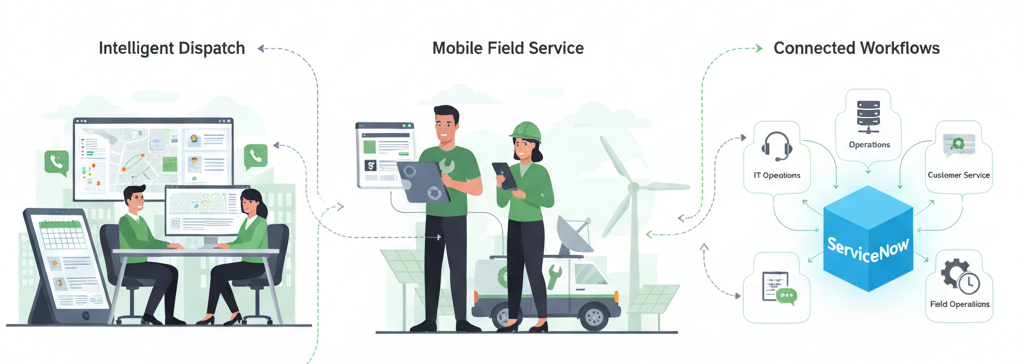

Implementation Highlights

Implementation focused on value realization rather than platform ambition.

The solution was rolled out incrementally, starting with pilot dealers. Adoption was driven not by mandates but by technician pull, because the system made their work easier.

Key design choices mattered:

- Continuous refinement based on real technician behavior

- Mobile-first usability for field conditions

- Minimal disruption to existing dealer workflows

- Relevance-based search instead of static navigation

The Outcome

The results were both measurable and meaningful.

Equipment uptime improved by approximately 15%, driven by faster diagnosis and higher first-time fix rates. Mean time to repair dropped as technicians spent less time searching and validating solutions. Dealers reported millions in cost savings, largely due to fewer repeat visits and better utilization of technician capacity.

Beyond metrics, the solution changed the service dynamic:

- Technicians felt supported rather than constrained

- Dealers saw tangible economic benefits

- The manufacturer strengthened its service value proposition without changing commercial models

This wasn’t a transformation driven by technology headlines but driven by execution realism. Operational gains like these often create the foundation for broader service revenue expansion, especially when uptime and reliability improve consistently.

The GenAI POC: A Conscious Decision Not to Scale

As part of the broader innovation agenda, the team also explored a GenAI-based proof of concept for technician support.

While the POC showed promise, it was ultimately not scaled. Governance concerns, response reliability, and ownership of generated guidance posed real risks, especially in safety-critical service contexts. More importantly, the cognitive self-service solution was already delivering strong outcomes, leaving limited incremental value from introducing generative AI at scale.

This decision reflected maturity, not hesitation.

Not every AI POC deserves production, especially when fundamentals are already working.

Lessons for Service Leaders

This case offers broader lessons for manufacturing and service organizations:

Digital service improvement starts with understanding technician cognition, not with selecting tools. Search often outperforms chat when precision matters. Dealer economics must be treated as a first-class design constraint. And restraint in AI adoption can be just as strategic as acceleration.

Most importantly, sustainable service transformation comes from making technicians more effective, not from making platforms more complex. This project reinforced a simple but powerful truth:

Digital transformation in service is not about doing everything at once but about solving the right problem at the right depth.

By focusing on technician experience and cognitive simplicity, the manufacturer unlocked measurable improvements in uptime, cost, and confidence, creating a foundation strong enough to support future innovation, including AI, when the time is right.