Field Service Strategy and Transformation

Modernizing field service for scale, efficiency, and resilience

This hub examines how field service organizations evolve their operating models, processes, and ways of working to meet rising customer expectations and workforce constraints. It covers practical transformation topics, from workforce enablement and process redesign to digital adoption through the lens of what actually works in complex, global service environments. The insights reflect hands-on experience with transformation programs where progress is measured by adoption and outcomes, not just system go-lives.

Core Field Service Insights

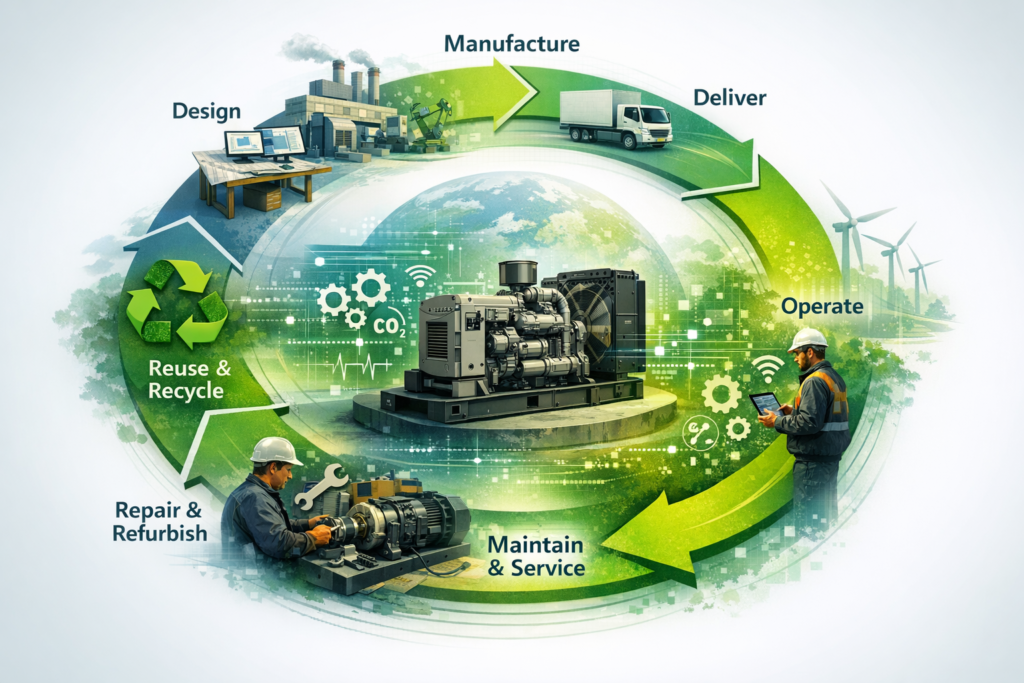

Sustainability & Aftersales: Why Lifecycle Thinking Is Manufacturing’s Real Climate Lever

Sustainability in manufacturing is decided long after the product leaves the factory. This article explores why aftersales and service execution, and not production alone, determine lifecycle impact, Scope 3 emissions, and customer value. By extending asset life through repair-first strategies, organizations unlock sustainability, margin growth, and stronger customer experience at the same time.

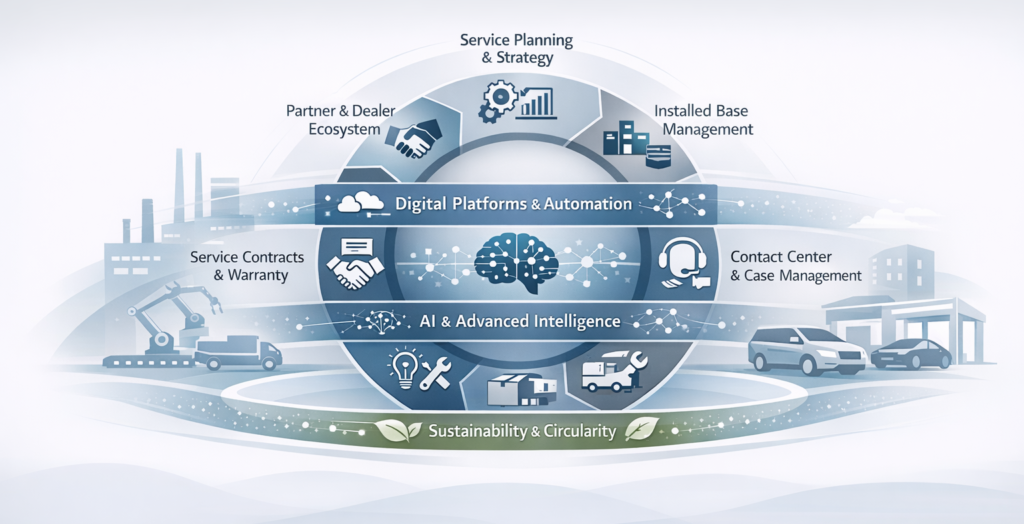

The Fully Autonomous Service Organization: What AI-Led Aftersales Really Looks Like

Aftersales is entering a new phase, one where service decisions are made before customers notice problems. This article explores what a fully autonomous service organization could look like, how AI-led orchestration changes warranty, parts, and dispatch, and why the shift is as much about operating models as technology.

Manufacturing & Automotive After-Sales Service: Strategy, KPIs & Digital Transformation

After-sales service is now a strategic growth lever for manufacturing and automotive organizations. This article presents an end-to-end view of after-sales service, covering operating models, KPIs, execution challenges, and the practical role of digital and AI, grounded in real-world service transformation experience.

Why Most Service Transformation Programs Stall After Year 2

Most service transformation programs don’t fail, they quietly stall. Early momentum, strong leadership attention, and rapid implementation create the illusion of success. But as priorities shift, budgets tighten, and ownership blurs, outcomes plateau. This article explores why service transformations lose momentum after year two, and what leaders must do differently.

2025 Aftersales & Field Service Review: From Ambition to Operational Reality

2025 was a reality-check year for aftersales and field service. Demand stayed resilient, but workforce shortages, asset complexity, AI scaling limits, and regulatory pressure reshaped execution. Leading organizations shifted from experimentation to fundamentals, anchoring AI to KPIs, prioritizing productivity over headcount, and treating service as an end-to-end system under real economic constraints across manufacturing and…

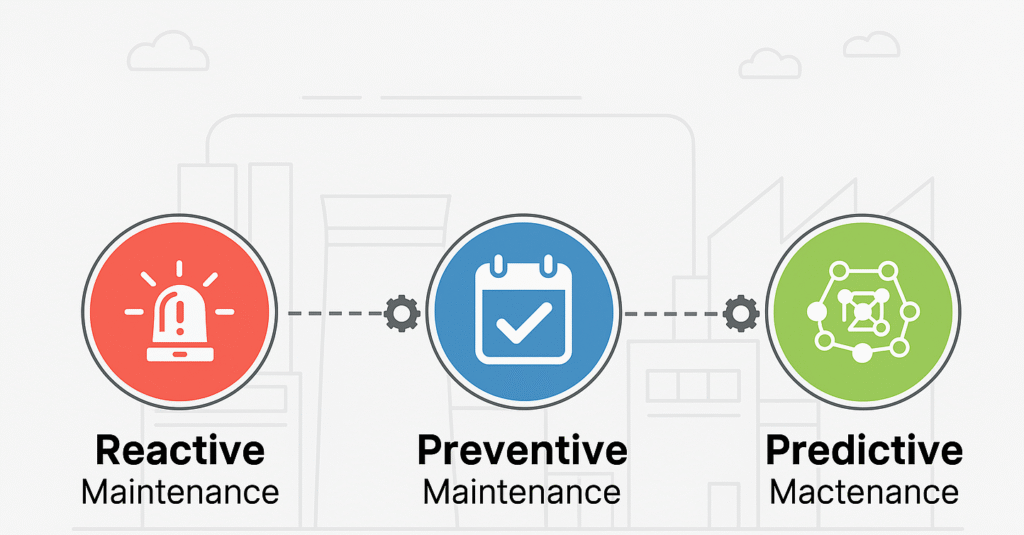

Predictive vs Preventive Maintenance: Key Differences Explained

Understand the real difference between predictive and preventive maintenance, and why it’s not just about technology. Learn how manufacturers can master preventive maintenance first, assess readiness, and layer predictive intelligence to drive service-led growth. Explore common pitfalls, readiness checklists, and practical guidance for bridging the gap from reactive repairs to proactive, data-driven reliability.

Featured Articles

Handpicked insights on the biggest shifts shaping after-sales and field service

Why Service Revenue Remains Untapped (Even When Everyone Has a Strategy)

Service revenue remains one of manufacturing’s biggest untapped opportunities. Many leaders have the strategy, but execution falters due to data gaps, weak change management, and unclear ownership. This article explores why most initiatives stall, what…

How AI Can (Actually) Help After-Sales Service – Beyond the Hype

Discover how AI is revolutionizing after-sales in industrial manufacturing – from complaint triage and technician scheduling to predictive maintenance and customer companion bots. This in-depth guide explores business challenges, real-world use cases, and measurable KPIs,…

The Field Service KPI Dashboard: What Executives, Managers & Technicians Should Really Track

A complete guide to field service KPIs by role, from executives to technicians. Learn which metrics drive profitability, efficiency, and customer experience. Based on the SmartServiceOps Field Service KPI Framework, this article helps service leaders…